Accessibility for Blind and Visually-Impaired Individuals

June 9th, 2021

At the start of this project, I first wanted to get a better understanding of the research space and existing work surrounding tactile graphics. I started off reading a few research papers and videos that show potential improvements to tactile graphics and methods of tactile communication.

Some papers of inspiration and relevance

Videos

In addition to existing research, we also looked over a few different existing products that currently assist BVL (Blind and Visually-Impaired) individuals with communication and task performance.

We discovered Swell Paper, a paper that creates “swells” or bumps in reaction to high temperatures. It is often utilized by tactile graphics machines to create braille messages or graphics. This heat sensitive paper began to spark some questions about ways this material might be used to serve functional purposes beyond printing from tactile machinery, which is both expensive and has limited access.

“How might we” statement

Swell Paper

To start, we experimented with different ways to make the Swell paper create bumps to measure the temperature that might be required for it to work. Although we received the carbon ink markers, the Swell paper did not change using a heat gun and light.

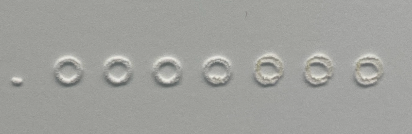

Because these temperatures did not seem to be producing visible changes in the paper, we used the heat from a laser cutter to first experiment with the material’s versatility.

However, because a laser cutter does not allow for any self-heating mechanisms and requires machinery, we began experimenting with ways to make a conductive circuit for the Swell paper to heat and “swell” up.

After creating some circuit designs to be laid on the Swell paper, we used a vinyl cutter to create stickers that would act as stencils for conductive ink to be painted onto the Swell Paper.

After cutting the stencils and placing it onto the Swell Paper, we then used a conductive ink to creating small circuits to generate heat on the material. However, the conductive ink circuits were not able to carry the current and became damaged before any visible changes were seen on the paper.

Afterwards, we then tried using copper tape instead of conductive ink as it is more likely to reach the required temperature of 110 degrees Celsius without damaging. Using the same circuits from before, we used the vinyl cutter to create more outlines onto the copper material and taped it to the Swell Paper.

After testing with the copper circuits, we were able to see visible results in the paper’s surface after heating! This gave us a better understanding of the required temperatures and the nature of the material, although the copper tape was unable to stay attached after the paper lifted from the surface.

Despite being successful in generating heat and creating a distinct tactile mark on the Swell paper, we wanted to find a more flexible medium that would allow the circuit to remain attached to the surface.